February 6, 2017

The following Grand Award recipients were chosen to compete for the coveted Pinnacle Award. These firms have shown excellence in innovation and creativity, as well as exceptional social, economic and environmental benefits through their work on the following projects.

Dunbar Milby Williams Pittman & Vaughan and Schnabel Engineering

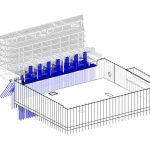

Dunbar Milby Williams Pittman & Vaughan provided structural engineering and Schnabel Engineering provided geotechnical and geostructural engineering for this significant project. The two firms collaborated on the design of the structural support and underpinning of the existing adjacent pavilion building, and design of the support of excavation and mat foundation for the new building.

Working space was limited and cluttered with utilities; deflection of nearby structures had to be limited to a very small magnitude; the foundation design had to account for future vertical expansion; the support of excavation needed to account for future below-grade expansion to the north; and the time that the excavation was open had to be kept to a minimum.

The project successfully consolidated many pediatric services into one building to provide comprehensive outpatient care under a single roof. This $200 million investment by VCU Health also improved the historic and vital Broad Street corridor of Downtown Richmond. The Children’s Pavilion was designed to meet the health care needs of children, and to provide Richmond the most advanced and coordinated care possible.

Froehling & Robertson

The National Museum of African American History and Culture was built on the last available parcel of land on the National Mall. The project faced several geotechnical challenges during construction. What was once a small tributary of the Potomac River is now primarily heterogeneous artificial fill and considered unsuitable to support the anticipated 11,500 ton building load of the museum. F&R’s subsurface investigation accomplished several goals for the design team, such as foundation design parameters, subsurface water recommendations and geothermal testing. Settlement in the surrounding structures was a major concern, as the museum would be located in close proximity to national landmarks. F&R used a hybrid foundation system of driven piles and mat foundation, as well as a dual-wall support of excavation to hydraulically isolate the structure. They also designed a sub-layer to collect and recycle any excess groundwater to be used within the museum.

Moffatt & Nichol

Moffatt & Nichol designed a replacement for Ship Repair Pier 5 at the Norfolk Naval Shipyard. The new Pier 5 can simultaneously support up to two U.S. Navy Ford Class aircraft carriers, or any other combination of Navy ships and barges. The new ship repair pier is 1,225-feet-long, 230-feet-wide, and is supported by over 1,200 36-inch-diameter precast, pre-stressed concrete cylinder piles. A new low-level relieving platform supporting mechanical and electrical shoretie stations replaced over 1,000 feet of existing wharf. More than 750,000 cubic yards of sediment from the berth area was dredged to attain a uniform, 47-foot dredge depth. Moffatt & Nichol designed the most critical components of the new Pier to last for a minimum of 75 years, as part of the Navy’s approach to extending their infrastructure’s service life. The final project design was delivered less than a year after contract award, and more than $20 million under the Navy’s construction estimates.

WSP | Parsons Brinckerhoff and SKW Constructors

The Hampton Roads region population has increased by nearly 70% since the existing Mid-town Tunnel was built leading to the tunnel’s usage to increase by nearly 600%. WSP|PB was the Lead Designer for the Elizabeth River Tunnels Project and were faced with rehabilitating three existing tunnels, designing the new tunnel, two buildings, five pump stations, ten bridges, flood control elements, six stormwater management ponds, and extensive environmental permitting before construction. WSP|PB created extended polystyrene embankment fills and lightweight fill to mitigate poor subsurface conditions. Flood walls berms were designed to mitigate potential flooding at the Norfolk approach to the tunnel. The tunnel was designed to meet current National Fire Protection Association standards, including a deluge system to control fire events in the tunnel. An egress system and longitudinal ventilation for the new tunnel using jet fans also contribute to the safety standards.

![acecvalarge[1] acecvalarge[1]](https://growthzonecmsprodeastus.azureedge.net/sites/636/2020/03/acecvalarge1-300x232.gif)